-40%

VACUUM BAGGING KIT -VACUUM BAG FILM, SEALANT TAPE, PEEL PLY, BREATHER, BLEEDER

$ 24.28

- Description

- Size Guide

Description

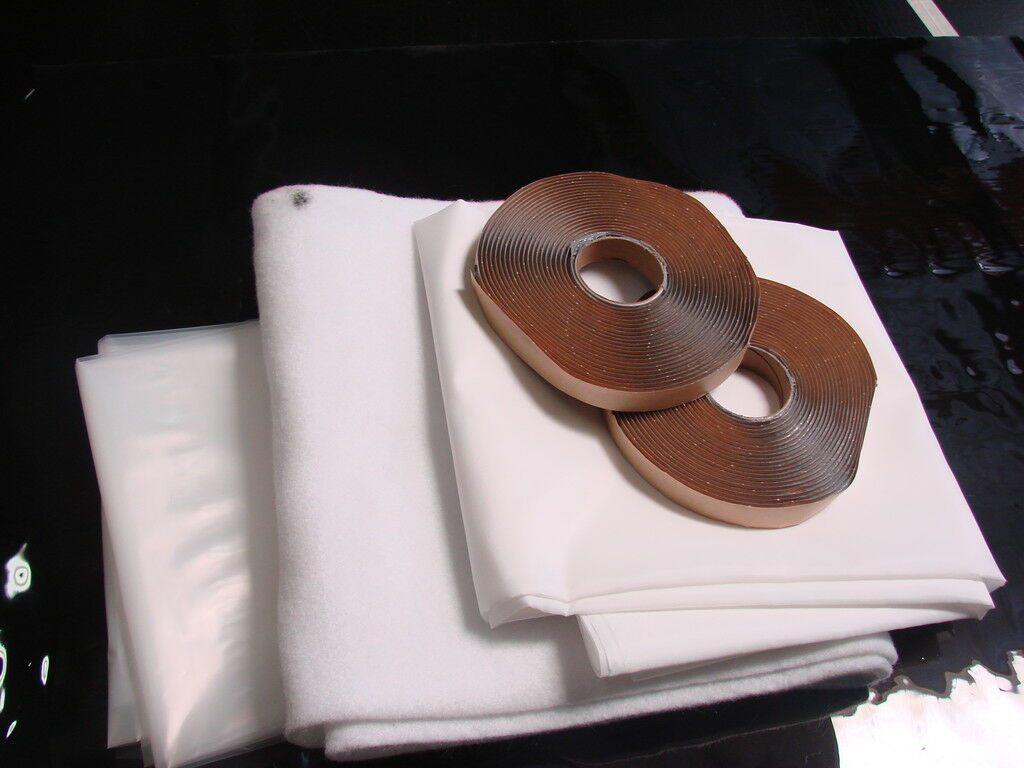

VACUUM BAGGING KITKit Includes

2 Rolls Gray Vacuum Sealant Tape

2 Yards By 60 Inches Wide Breather Polyester Peel Ply

2 Yards By 60 Inch Wide 4 Ounce Breather Cloth

2 Yards By 60 Inches Room Temperature Or Heat-cure (350°F Max) Vacuum Bagging Film

VACUUM BAGGING KIT comes with all the necessary components needed for a vacuum bagging operation of up to <60-inch wide (depending on the height of the part) by 60-inch long part.

It can also be used for resin-infusion, VARTAM and heat cured/autoclave curing of the structural- strength laminating process.

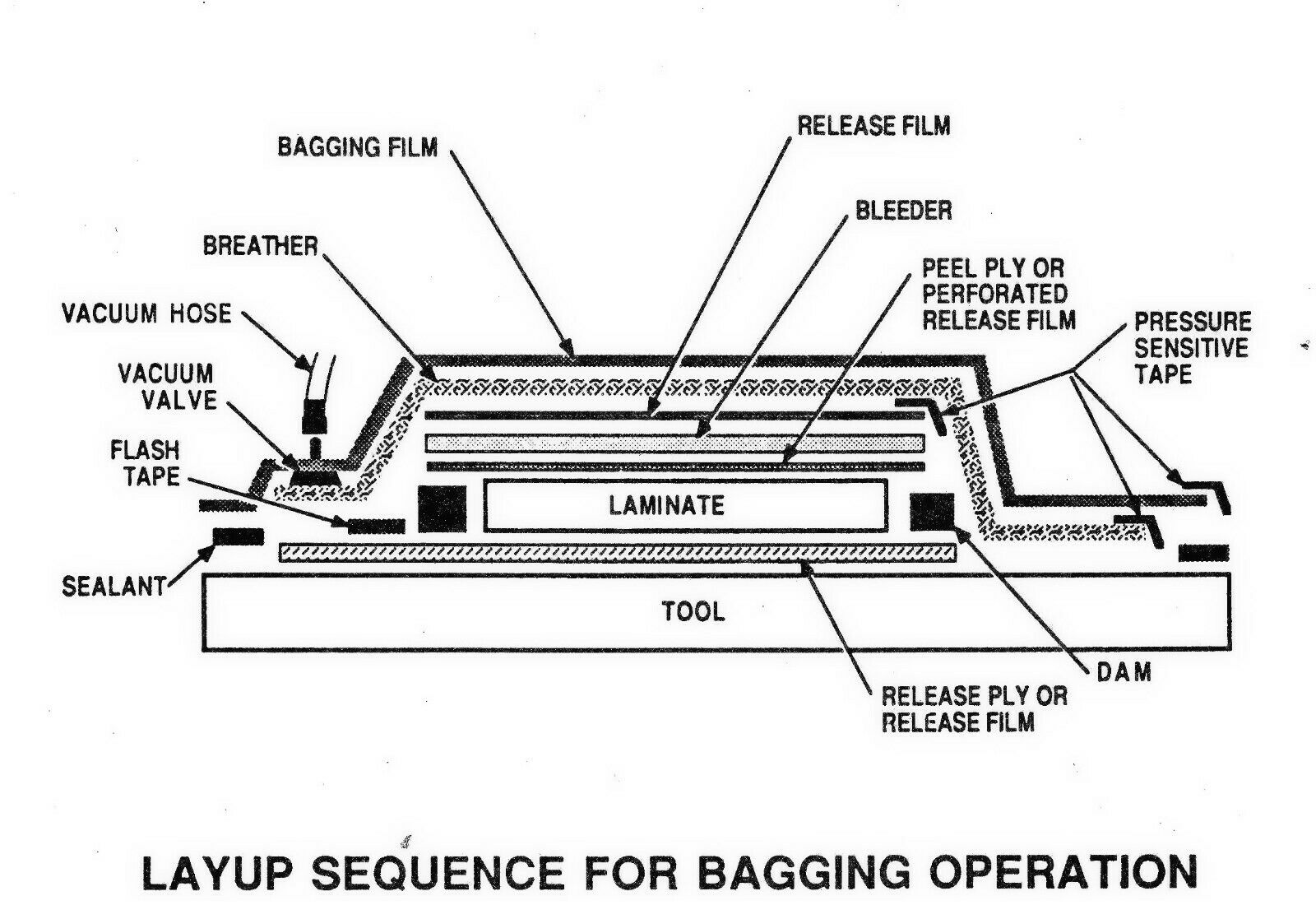

Vacuum bagging (or vacuum bag laminating) is a method that uses vacuum pressure to

consolidate the composite lay-up.

The laminate is vacuum bagged until the polymer resin cures and effectively consolidates all the fabric and resin to a homogenous and void-free FRP laminate.

Cured laminates demonstrate higher mechanical properties due to the complete integration and resin distribution of the composite laminate.

The vacuum bagging process can also be used for applying uniform pressure to the adherents or substrates in bonding or laminating process while the adhesive cures and develops the physical bond.

Vacuum bagging

is commonly used for high performance composite structures and traditional wood veneering and in large and small bonding applications.

For Vacuum Bagging Process

Multi Plywood Sheet Wood Transom Vacuum Laminated With

MAX BOND LOW VISCOSITY

https://www.ebay.com/itm/311947117608

2 Plies of 3/4 Inch Plywood Vacuum Laminated

Vacuum Bagging Theory

Vacuum bagging uses negative atmospheric or vacuum pressure to hold laminate plies together.

The laminate is sealed within an airtight envelope and the internal atmosphere within the envelope is evacuated by a vacuum pump to full vacuum pressure.

Perfect vacuum can only be achieved in the absence of atmosphere or in deep outer space.

In many instances, 27 to 29 inches of Mercury (Hg) is sufficient vacuum pressure to produce a well consolidated composite laminate.

14 Pounds Per Square Inch Of Consolidation Pressure Is Applied At 29 In Hg Vacuum Pressure.

EPOXY RESIN FOR VACUUM INFUSION OR

DRY LAY-UP VACUUM BAGGING WITH

MAX 1618 1.5 GALLON KIT

https://www.ebay.com/itm/311946441558

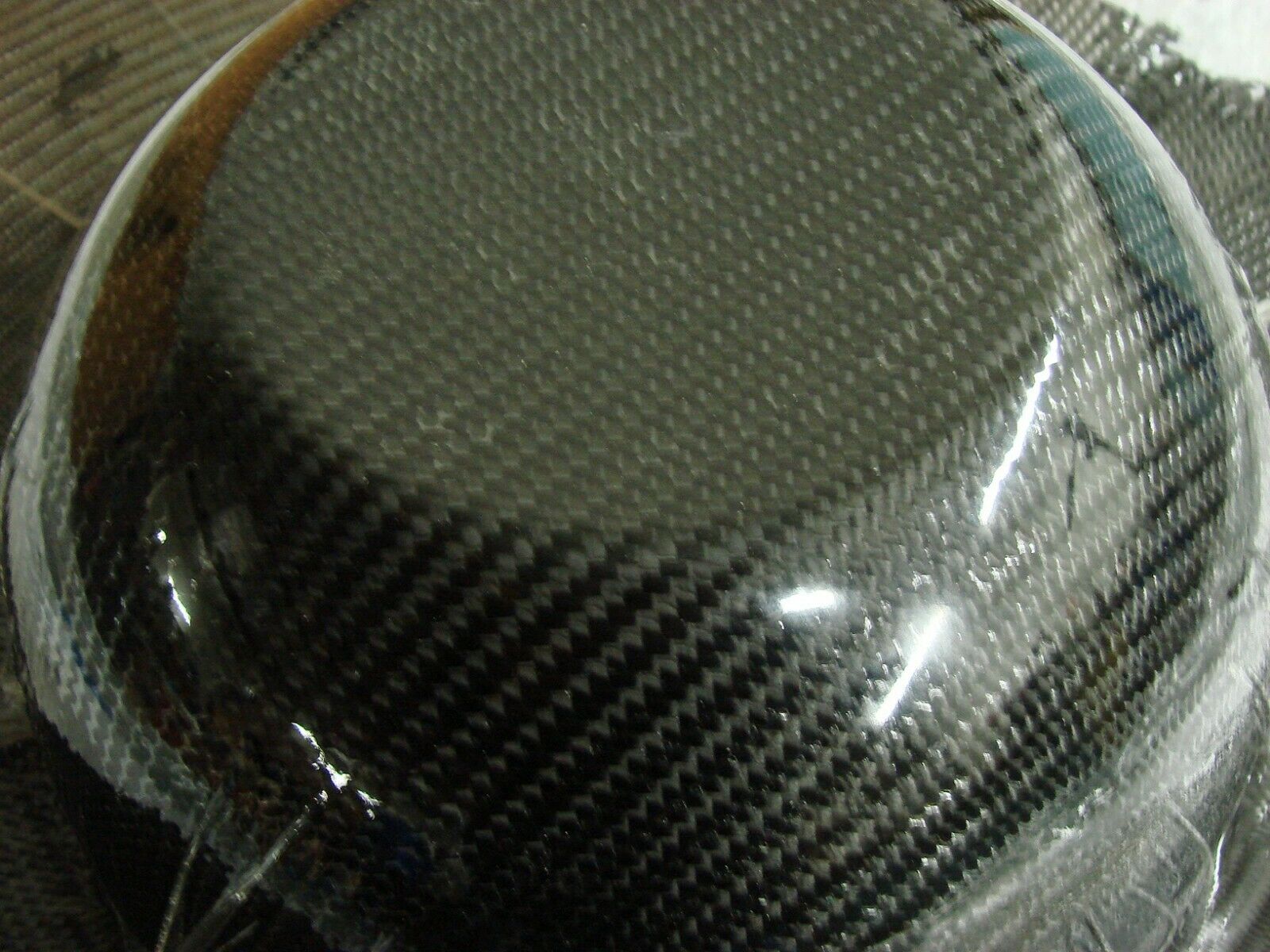

12 Plies Of Carbon Fiber Laminate With MAX 1618 A/B And Vacuumed Bagged.

General Principle Of Vacuum Bagging

General Principles of Vacuum Bagging

Video will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]

MAX 1618 A/B VACUUM ASSISTED RESIN TRANSFER MOLDING PROCESS

VACUUM INFUSION VIDEO

(Green Flow Media Sold Separately)

Vacuum Infusion With MAX 1618 A/B

Video will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]

Fiberglass Tooling Board With MAX 1618 A/B

48" x 96" 20 Plies

7500 Fiberglass Fabric (

https://www.ebay.com/itm/312585593625

)

ULTIMATE COMPRESSIVE STRENGTH TEST OF Fiberglass Tooling Board Compressive Test

Video will open in a new window

Compressive Load 6500 Pounds To Failure

Divided By .0.498 Square Inch (

Length

x Width)

=

13,052 PSI Maximum Compressive Strength

PLEASE CHECK OUT OTHER AVAILABLE

RESIN SYSTEMS AT OUR eBay STORE

For our complete listing, please

Visit our eBay store!

DON'T FORGET OUR EPOXY MIXING KIT

Click The Link To Add To Order

https://www.ebay.com/itm/222623932456

EVERYTHING YOU NEED TO MEASURE, MIX, DISPENSE OR APPLY

Proportioning the correct amount is equally as important to attain the intended cured properties of the resin system.

T

he container in which the epoxy and curing agent is mixed is an important consideration when mixing an epoxy resin system.

It must withstand the tenacity of the chemical and must be free of contamination.

Most epoxy curing agent has a degree of corrosivity, as a general practice, protective gloves should be worn when handling chemicals of the same nature.

MIXING KIT CONTENTS

1 Each Digital Scale -Durable, Accurate Up To 2000.0 Grams

4 Each 32-ounce (1 Quart) Clear HDPE Plastic Mix Cups

4 Each 16-ounce (1 Pint) Clear HDPE Plastic Mix Cups

One Size Fits All Powder-Free Latex Gloves

2 Each Graduated Syringes

Wooden Stir Sticks

Assorted Size Foam Brush

IMPORTANT NOTICE

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product.

The user should thoroughly test any proposed use of this product and independently conclude the satisfactory performance in the application.

Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval.

The information contained herein is based on data believed to be accurate at the time of publication.

Data and parameters cited have been obtained through published information, PolymerProducts and Polymer Composites Inc. laboratories using materials under controlled conditions.

Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this products fitness for use.

There is no warranty of merchantability for fitness of use, nor any other express implied warranty.

The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period.

Polymer Composites, Inc and its direct representative will not be liable for incidental or consequential damages of any kind.

Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.