-40%

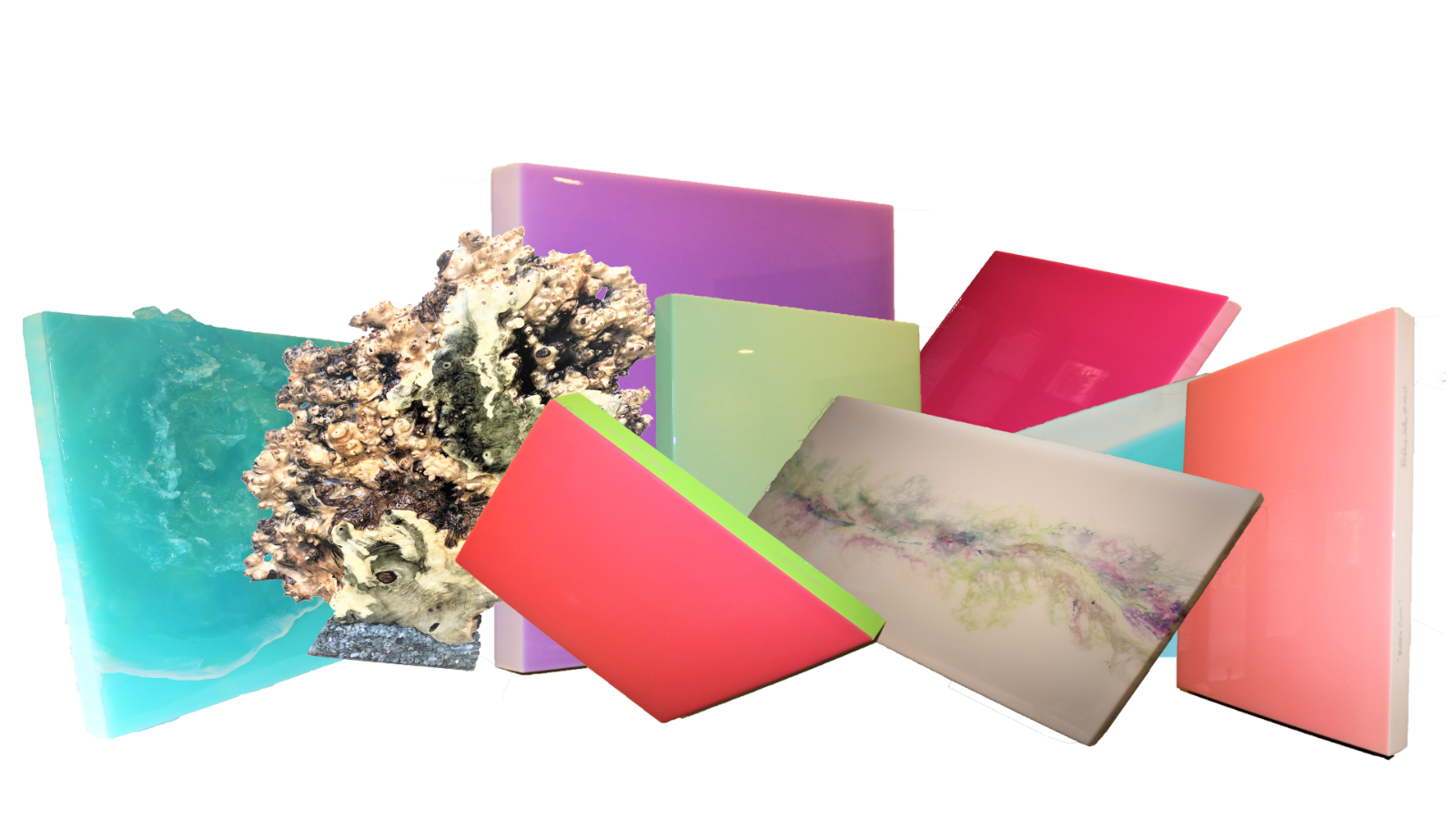

Rockstar - 4-Star Epoxy Casting Resin - 2 Gallon Kit (3:1 Mix) Rock Hard

$ 62.7

- Description

- Size Guide

Description

4-Star Casting Resin - 2 Gallon Kit (3:1 Mix) - No Torch NeededOur 2 Gallon Kit gets you on stage to making some water clear, bubble free, and rock hard casting pieces. Our casting product is recommended for the following applications:

JEWELRY MAKING

COASTERS

PAPER WEIGHTS

EMBEDMENTS

GLOBES

MOLDS

Our 3:1 easy measure formula has a dry time of 36 hours and cures fully in 72 hours. Casting resin is a thin viscosity formula allowing for fantastic bubble release without any need for torching.

This Epoxy Resin pours and levels out to 1/8" per pour on any flat surface. Extensive tests have shown that you will be able to do multi-inch pours without the risk of the epoxy overheating which often happens with common 1:1 formulas.

Kit Includes:

1 - 192oz. of Epoxy Resin

1 - 64oz. of Hardener

1 - Instruction Guide

Rockstar 4-Star Premium Epoxy Resin is a 100% solids,high-build, clear polymer coating that is commonly used in resin jewelry, tumblers, table tops, coasters, and artwork coatings. Each kit contains a bottle of resin and a bottle of hardener which are mixed together at a 3 to 1 ratio by volume. This product cures to a clear, glass-like finish that resists scratching and will not distort with age. Items coated with it will become permanently preserved and protected for your enjoyment throughout a lifetime. This product will resist yellowing and is water resistant. However, no product provides 100% UV protection. This should be carefully considered before applying in an outdoor, high UV exposure setting. Rockstar Resins

will not exhibit any blushing or sweat-out even under high humidity conditions. This product is best applied in two stages. The first stage is referred to as the seal coat. The seal coat is brushed on in a thin layer and is used to seal any porosity on the surface which will prevent air bubbles from rising in the subsequent flood coats. Once the seal coat has set for at least 4 hours a flood coat is then applied. The flood coat should be poured onto the surface and allowed to flow out and self-level. You can use a rubber squeegee or a foam brush to help spread the epoxy. Generally one to three flood coats are applied for most table and bar coatings, however you must wait between 4 to 10 hours before applying subsequent flood coats. What You Need: ? Safety Gloves - Epoxy is very sticky. ? Graduated Mixing Cups - Accurate measurement is extremely important to achieve optimum cured properties. ? Clean Stir Sticks - Dirty sticks can cause contamination of the epoxy. ? Rubber Squeegees - These spreaders will not leave air bubbles behind as brushes can. ? Brushes - Foam or nylon brushes which do not lose bristles ? Solvent - Denatured alcohol or acetone for cleanup and wiping ? Propane Torch, Heat Gun or Hair Drier - Used by sweeping the heat or flame across the surface of the uncured

epoxy to release trapped air bubbles ? Drop Cloths - Should be used to avoid spills on flooring surfaces Beginners Notes: This product will produce professional results when applied correctly. Take your time to review some of these common problems that first time users can encounter. 1. VERY IMPORTANT: To avoid most of these common problems, you should always do a trial run with the product to insure proper understanding of how to mix and apply. 2. Always make sure that your mixing container is clean and your measuring device is accurate. This product requires that you mix at a 3 to 1 ratio by volume. Any variances from this ratio will cause the epoxy to never completely cure. 3. THOROUGH mixing is the most important part of this procedure. Even if you have experience with other types of resins, it is very easy to underestimate the amount of mixing this product requires. Depending on the quantity being mixed, it can take anywhere from 3 to 7 minutes of continuous mixing without whipping. During mixing the product will turn cloudy white and you must continue to mix until all signs of haziness and white streaks in the mixture have turned back to a completely transparent color. 4. Do not whip this product while mixing. Lifting the stick while mixing can excessively whip the product and will add a tremendous amount of air bubbles which are difficult to remove. 5. Always scrape the sides of the mixing container and stick during the mixing process. If any unmixed material remains on the side of the container and falls onto your surface while pouring it will leave an uncured wet or sticky spot. 6. While pouring the epoxy onto the surface, NEVER scrape or brush the sides or bottom of the container you just mixed in to remove every last drop because no matter how thoroughly you may have mixed, there will always be an unmixed portion stuck which can be dislodged and will leave a wet or sticky spot. 7. Never leave mixed epoxy in your bucket unattended. The longer the epoxy sits in your bucket, it will increase the chances that the epoxy will generate excess heat, begin to smoke and then cure quickly inside the bucket. 8. Cleaning the cured finish should only be done with mild soap and water. Using harsh cleaners or kitchen chemicals can cause the finish to feel tacky.